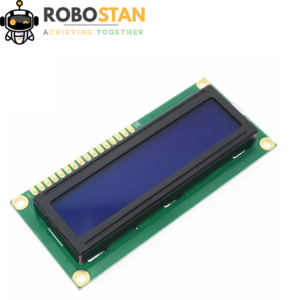

LCD (Blue/Green) 20×4

350 in stock (can be backordered)

Pinout

| Pin | Symbol | Function |

|---|---|---|

| 1 | Vss | ground (0 V) |

| 2 | Vdd | 5 V logic supply voltage |

| 3 | Vo | contrast adjustment |

| 4 | RS | H/L register select signal |

| 5 | R/W | H/L read/write signal |

| 6 | E | H/L enable signal |

| 7-14 | DB0 – DB7 | H/L data bus for 4- or 8-bit mode |

| 15 | A (LED+) | backlight anode |

| 16 | K (LED-) | backlight cathode |

₨900 ₨1,050

350 in stock (can be backordered)

CompareLCD (Blue/Green) 20×4

This LCD (Blue/Green) 20×4 has 20-character, 4-line parallel liquid crystal display provides a large viewing area. It features white text on a blue background with an LED back-light and uses the common HD-44780 interface, so sample interface code is widely available for a variety of micro-controllers. This display is electrically compatible with the LCD that is included as part of some of our Orangutan X-2 robot controller packages, although the physical interface is different. Data Sheet download link is here and link of Facebook is Embeded Studio

Instructions

Outline

Only the instruction register (IR) and the data register (DR) of the HD44780U (LCD (Blue/Green) 20×4) can be controlled by the MPU. Before starting the internal operation of the HD44780U(LCD (Blue/Green) 20×4), control information is temporarily stored into these registers to allow interfacing with various MPUs, which operate at different speeds, or various peripheral control devices. The internal operation of the HD44780U is determined by signals sent from the MPU. These signals, which include register selection signal (RS), read/ write signal (R/:), and the data bus (DB0 to DB7), make up the HD44780U instructions.

There are four categories of instructions that:

- Designate HD44780U functions, such as display format, data length, etc.

- Set internal RAM addresses

- Perform data transfer with internal RAM

- Perform miscellaneous functions

Normally, instructions that perform data transfer with internal RAM are used the most. However, autoincrementation by 1 (or auto-decrementation by 1) of internal HD44780U RAM addresses after each data write can lighten the program load of the MPU. Since the display shift instruction (Table 11) can perform concurrently with display data write, the user can minimize system development time with maximum programming efficiency. When an instruction is being executed for internal operation, no instruction other than the busy flag/address read instruction can be executed. Because the busy flag is set to 1 while an instruction is being executed, check it to make sure it is 0 before sending another instruction from the MPU.

Precautions in use of LCD Modules

- Avoid applying excessive shocks to the module or making any alterations or modifications to it.

- Don’t make extra holes on the printed circuit board, modify its shape or change the components of LCD module.

- Don’t disassemble the LCM.

- Don’t operate it above the absolute maximum rating.

- Don’t drop, bend or twist LCM.

- Soldering: only to the I/O terminals.

- Storage: please storage in anti-static electricity container and clean environment.

- Supplier had the right to change the passive components, including R3,R6 & backlight adjust resistors. (Resistors, capacitors and other passive components will have different appearance and color caused by the different supplier.)

- Supplier has the right to change the PCB Rev. (In order to satisfy the supplying stability, management optimization and the best product performance…etc, under the premise of not affecting the electrical characteristics and external dimensions, Vishay has the right to modify the version.)

Based on 0 reviews

Be the first to review “LCD (Blue/Green) 20×4”

You must be logged in to post a review.

There are no reviews yet.